Utility Services is continuously seeking to improve operations. We regularly conduct studies to identify new opportunities to save energy and resources. We also have numerous ongoing and upcoming planned capital projects to support the three campuses' infrastructure and Utility Plants.

Most often, projects are implemented to:

- Reduce costs

- Manage appropriate redundancy in case of emergency

- Increase energy efficiency

- Replace ineffective equipment or systems

- Increase service capacity

Recent Projects

2015 — 2016

- City Campus, new Thermal Energy Storage (TES) Plant

- 19th Street Steam & Chilled Water Service Tunnel

- City Campus Plant, De-aerator Replacement and Instrument and Controls Shop

- City Campus, Westside Chilled Water Loop Extension

- City Campus Plant, Rebuild Turbine and Controls on Chiller #3

- East Campus Plant 5 KV Switchgear Replacement

- Campus Domestic Water Service Booster System

2014 — 2015

- Innovation Campus, Central Renewable Energy System (CRES) Plant

- City Campus Plant, East Cooling Tower Replacement

- East Campus Plant, Chiller 4 & 5 Addition

- City Campus, Beadle Center Heat Recovery Chiller

2013 — 2014

- City Campus Plant, North Cooling Tower Replacement

- City Campus Plant, New 1.5MW Emergency Generator Installation

- City Campus Plant, Replacement 12.KV Swithgear

Project Highlight: Beadle Center Heat Recovery Chiller

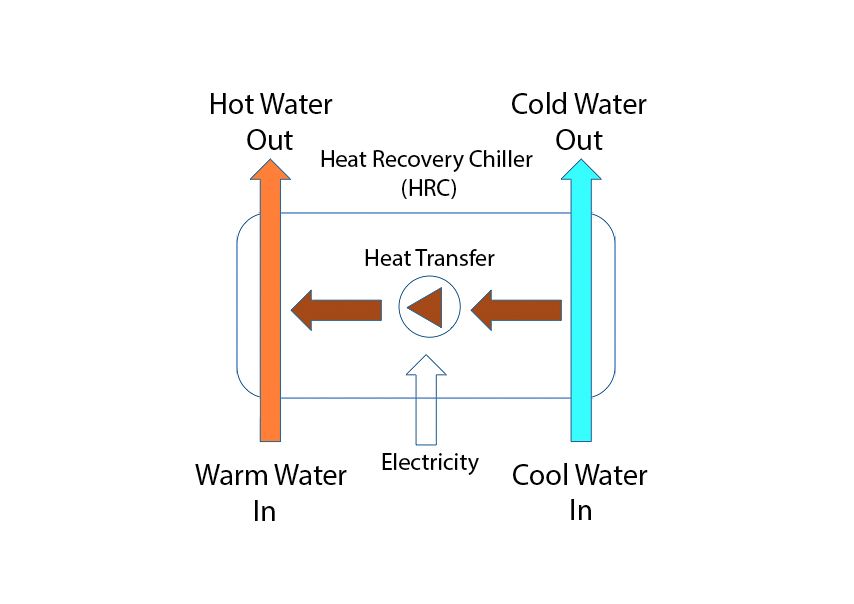

In late 2014, the University of Nebraska-Lincoln installed a Heat-Recovery Chiller, or HRC, in the basement of the Beadle Center on City Campus. The HRC is about the size of a large residential refrigerator and uses electricity to produce hot and cold water to condition the building.

The Beadle Center already uses campus steam and chilled water for its heating and cooling needs and will continue to use those commodities. The HRC reduces the load on campus utilities and saves energy and related costs by producing some of the hot and cold water on-site.

Over the last few months, the HRC has exhibited average coefficients of performance of at least 3 and 2, for heating and cooling respectively. This means that for every unit of electricity going into the HRC, it produces both 3 units of heating water and 2 units of cooling water.

The process isn’t magic and doesn’t violate laws of thermodynamics. Like a refrigerator, the HRC uses electricity to drive a compressor which moves heat from cool water to warm water, making the cool water colder and the warm water hotter. Unlike a refrigerator, the HRC captures and uses both heating and cooling energy at the same time, allowing it to produce 5 or more units of heating and cooling for each unit of electricity consumed.

Because the relative prices of campus chilled water, steam and electricity are different, the economic advantage factor is about 3.5 – for every dollar of electricity input, the HRC delivers $3.50 worth of heating and cooling to the building. All heating is used within the Beadle Center, but if excess cold water is produced, it’s fed back into the campuswide chilled water system.

The total project cost was $190,000, which was paid from utility funds from the vice chancellor’s office. It is expected to have a simple payback of about 6 years. A similar HRC is being designed for the east wing of the Beadle Center, and Facilities Maintenance and Operations is considering other locations where HRCs would be appropriate.