A system built for continuous operation is the norm for any campus utility infrastructure. Because our services are critical and end users do not tolerate disruption, redundancy in equipment and sophisticated plans for maintenance are built into plant operations.

Keeping Things Running

Plant equipment and distribution items are designed for up to 50-year life spans (with some expected variation) as long as good maintenance practices are employed. The Facilities Maintenance and Operations Division, including our Utility Services group, uses a common computerized maintenance management system (CMMS) to improve our ability to engage in proactive maintenance.

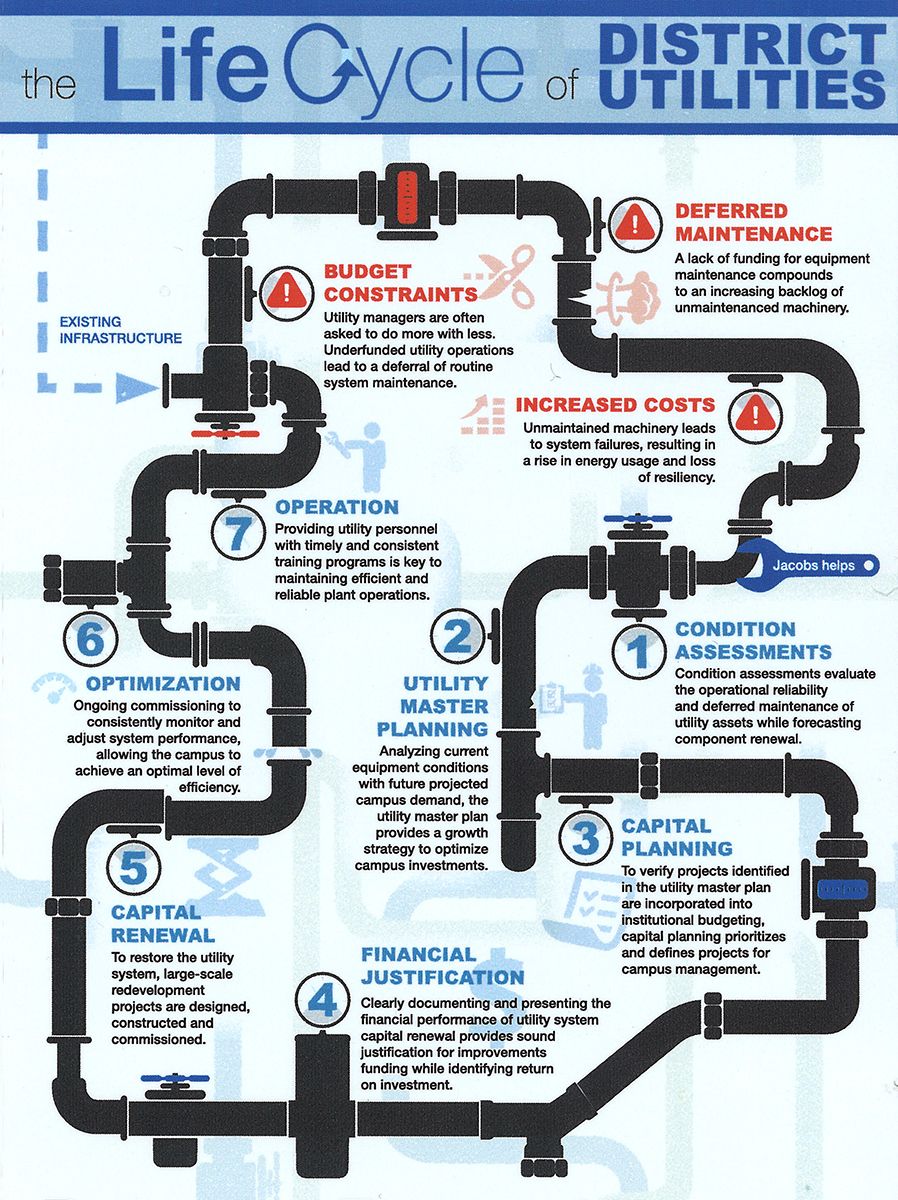

The following graphic illustrates the many facets of planning for and coordinating maintenance to ensure uninterrupted operation.

By engaging in proactive maintenance planning and coordination, Utility Services is proud to be able to:

- Employ automation technologies in all systems

- Establish a long-term funding structure

- Incorporate utility plans into campus master plans

- Increase reliability with safer equipment and energy efficiency with sustainability-minded technologies

- Reduce the need for / use of hazardous chemicals