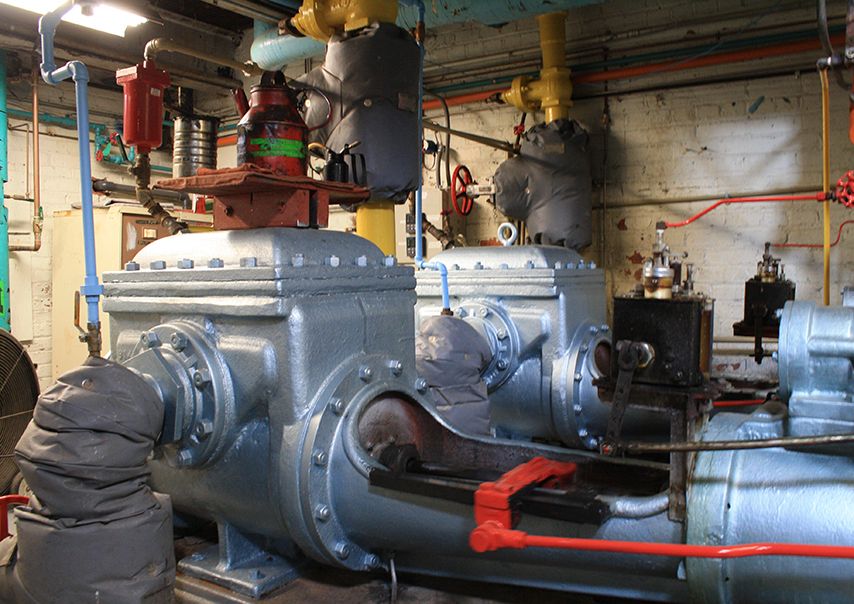

The East Campus Utility Plant (ECUP), originally built in 1915 as a coal-fired heating plant, is one of the oldest buildings on campus. Located just north of the Larsen Tractor Museum, it generates and distributes steam and chilled water to provide heating and cooling to East Campus. During a century of operation, the ECUP has seen numerous equipment updates to meet today's industry and environmental standards. Yet, well-maintained equipment such as a pair of 1917 American-Marsh steam-driven condensate return pumps still remains operational.

General Statistics

Underground steam distribution pipes: 4.7 miles

Buried chilled water pipeline: 3.6 miles

Electrical disitributions: 8.0 miles

Domestic drainage: 11.7 miles

Sanitary drainage: 7.3 miles

Storm drainage: 9.7 miles

Chilled water temperature: 42°F

Distribution steam temperature: 292°F

Equipment and Fuel Profile

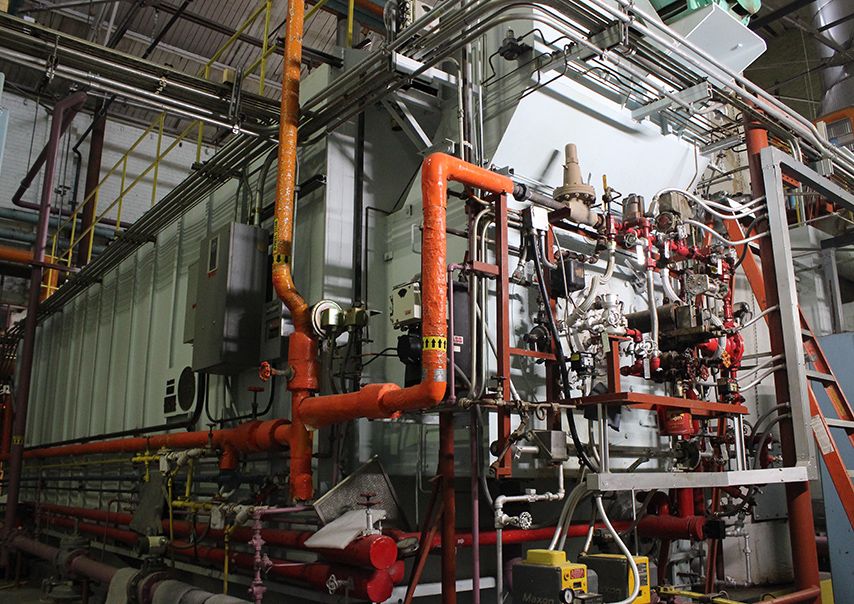

Utility plant fuel source: Clean Natural Gas, Number 6 Fuel Oil

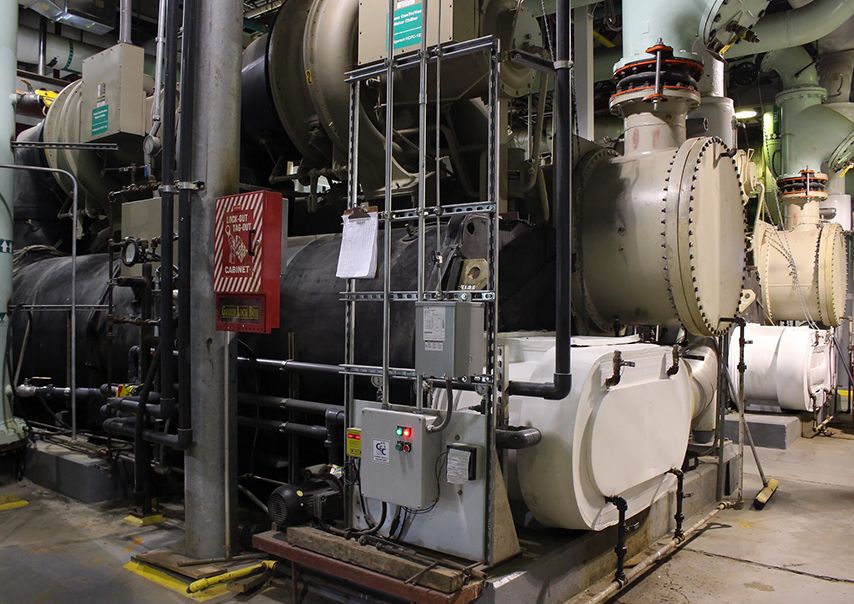

Number of chillers: 3 @ 7.5 ktons/hr

Number of dual-fuel boilers: 3 @ 220 klbs/hr

Campus distribution steam pressure: 60 psi, saturated

Number of cooling towers: 2

Operations

The East Campus Utility Plant operates around the clock and is managed by four shifts of two-person crews consisting of operators. The plant also houses three maintenance personnel who perform regular plant maintenance and repairs and also two standby personnel who can function either as maintenance or in operator capacity. ECUP operators monitor equipment status and electricity load and remotely monitor the Thermal Energy Storage (TES) system from their computer screens in the operations room.

Current plant equipment includes three dual-fuel boilers that primarily burn clean natural gas and three electric motor-driven chillers. Even as newer equipment gets added to the plant, well-maintained machinery such as a pair of 1917 American-Marsh steam-driven condensate return pumps still remains operational.

The ECUP ceased generating its own electricity in the 1960s in part due to the high operational and maintenance cost of the steam turbine generators. Instead, the utility plant has purchased electricity from municipal providers such as Lincoln Electric System (LES).

Increasing Efficiency in Heating and Cooling

The East Campus Utility Plant provides year-round heating and cooling to East Campus. Pressurized steam is delivered to campus buildings through pipes in underground tunnels while chilled water is delivered by means of buried pipelines.

ECUP has also built a Thermal Energy Storage (TES) tank which functions like a geothermal heat pump that will aid in the building cooling process while reducing the use of fossil fuel. Learn more about the TES.

READY TO BLOW THEIR TOPS

Did you know: the boilers of yesteryear had the potential to explode due to underdeveloped safety technology. To isolate the effects of a possible explosion and prevent extensive structural damage, plant roofs like the ECUP's were typically constructed out of thin wood planks, in contrast to the thick, brick-layered walls. If a boiler exploded, pressure could be directed up and out of the roof instead of damaging the sidewalls.

Luckily, the ECUP never experienced a boiler explosion incident to put this design to the test.

History

The original East Campus heating plant and underground steam tunnels were built in the early 1890s. The plant was situated in the northeast corner of the current Hardin Hall footprint. Two coal boilers supplied steam to a small number of campus buildings and barns to keep building occupants and livestock warm during the winter.

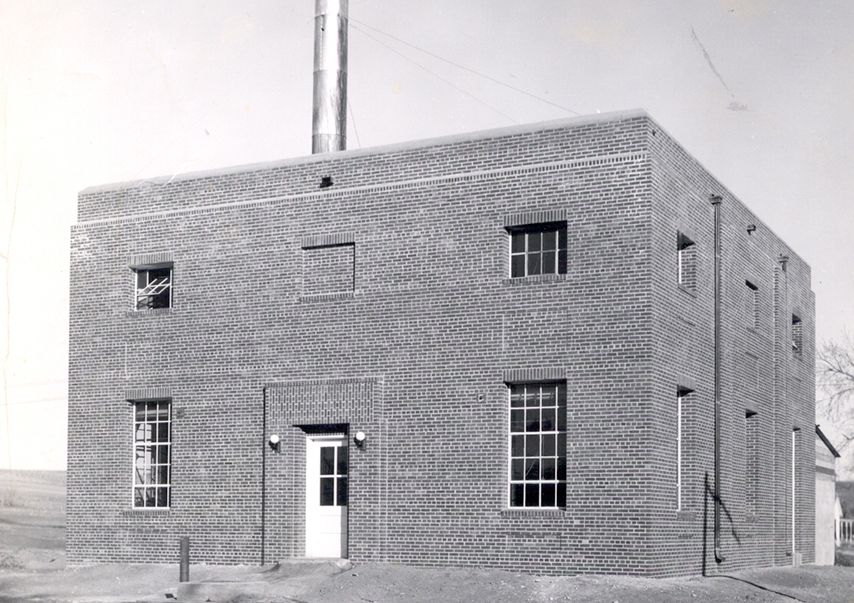

As the campus expanded over the years, the heating capacity of these coal-fired boilers was unable to keep up with growing heating demands. Because the original location was unfit for expansion, the original plant was torn down and rebuilt in its current location in 1915 to take advantage of its low elevation to ease the return of condensate back to the plant. Trains delivered carts of coal to be used as fuel source in the four brick-set boilers for steam generation up until the early 1950s.

The ECUP experienced a horizontal structural expansion as spaces were created to accommodate new equipment. Additions included a powerhouse with a piston-driven, open-flywheel electric generator that was attached in the 1920s. A steam-powered water chiller was added in 1965 to help provide additional comfort to campus building occupants and livestock and also assist in research process load.

Over the years, newer equipment with better safety and environmental standards replaced older models as investments and technology became available. However, the original coal boiler stack from 1915 still stands tall as a landmark and a reminder of the building's long history of service to UNL's East Campus.