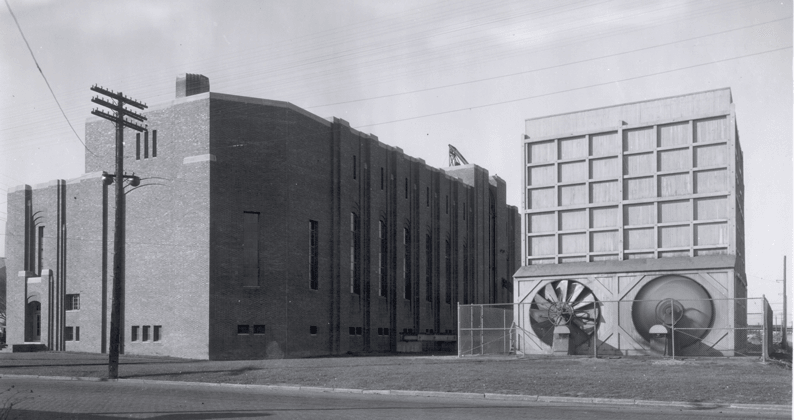

The City Campus Utility Plant (CCUP), originally built in 1929-30 as a coal-fired heating plant, is one of the oldest buildings on campus. Located just north of the Campus Recreation Center, it generates and distributes steam and chilled water to provide heating and cooling to City Campus and some government buildings in downtown Lincoln, including the Capitol. The CCUP has undergone multiple building modifications over the years to accommodate new equipment and modifications, meeting today's industry and environmental standards.

General Statistics

Underground steam distribution pipes: 6.0 miles

Buried chilled water pipeline: 7.4 miles

Electrical distributions: 10.7 miles

Domestic drainage: 22.6 miles

Sanitary drainage: 23.4 miles

Storm drainage: 24.6 miles

Chilled water temperature: 42°F

Distribution steam temperature: 325°F

Equipment and Fuel Profile

Utility plant fuel source: Clean Natural Gas, Diesel, Number 6 Fuel Oil

Number of chillers: 7 @ 23 ktons chilled water/hr

Total number of dual-fuel boilers: 4 @ 360 klb steam/hr

Campus distribution steam pressure: 35 psi, superheated

Number of cooling towers: 3

Operations

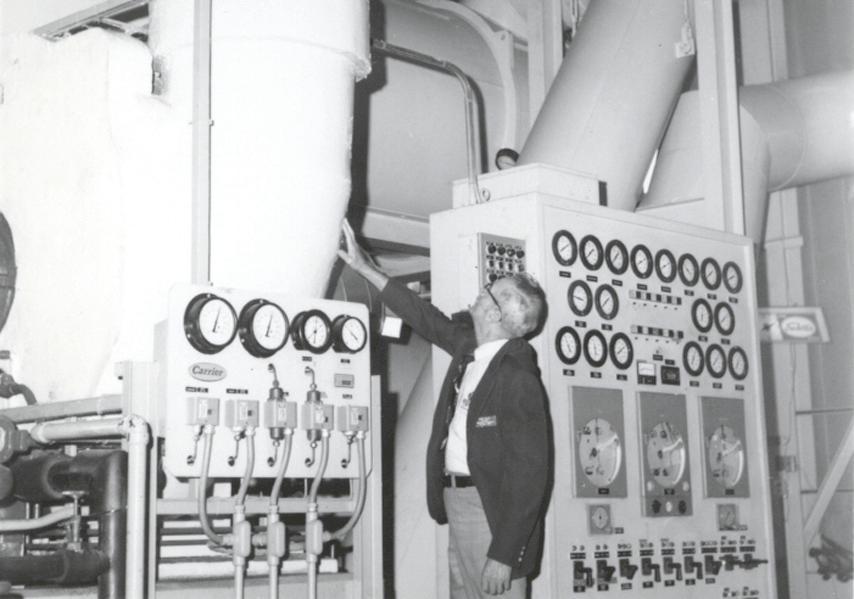

The CCUP runs day and night and is managed by five shifts of operators, including a chief operator and two junior operators. These operators occupy the operations center and monitor equipment and system statuses through live data that is fed into computerized reporting systems. In addition, they physically inspect machinery and take readings at hourly intervals. CCUP operators also remotely monitor the Centralized Renewable Energy System (CRES) at Nebraska Innovation Campus.

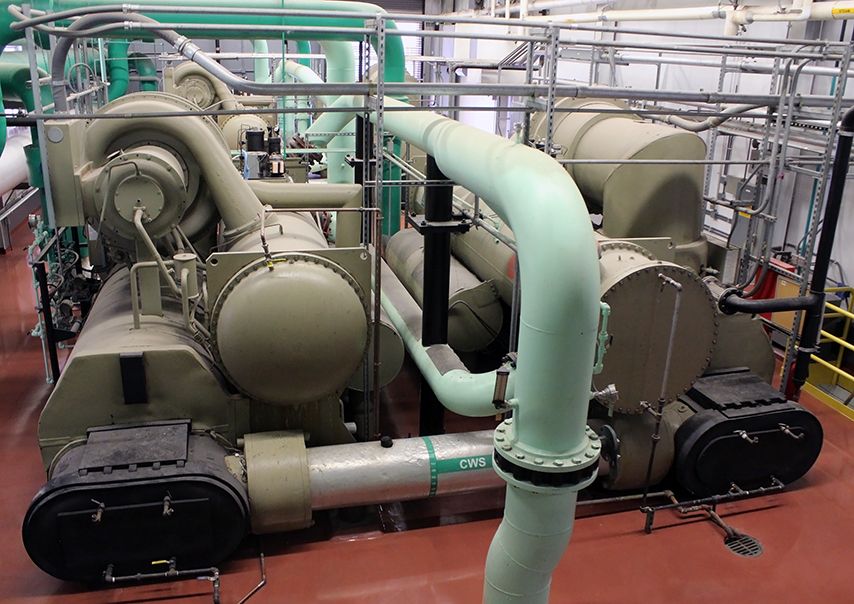

The plant also relies on a crew responsible for regular maintenance and repair work and an in-house chemist, who serves each of the campus plants. Water chemistry plays an important role in utility plants because equipment like boilers, chillers and (miles of) underground steam and chilled water pipes can corrode or suffer damage from biological growth if not properly maintained. As such, water is properly treated and prepared by the chemist before it is utilized in plant equipment.

Focused on Heating and Cooling

At the turn of the 21st century, UNL entered into a utilities contract to source electricity from both Lincoln Electric System (LES) and Western Area Power Administration (WAPA), which is then delivered to the campus utility plants to be distributed among campus buildings. UNL recognized that as mass producers of electricity, LES and WAPA are able to generate electricity at a lower cost and with greater efficiency. In fact, a large portion of power that is being delivered to City Campus is sustainably sourced from WAPA’s hydropower plant on the Missouri River. With the elimination of power generation at the plant, its operations now focus on year-long heating and cooling.

Fuel beyond electricity is required, though, to generate steam. The plant has boilers that allow dual fuel capabilities to burn clean natural gas and diesel as a backup. The power plant switched from coal to natural gas in the 1950s and uses fuel oil as a backup to clean natural gas.

DO YOU KNOW ABOUT THE FIREMEN?

Chief operators were also called firemen when the utility plants still used coal as the main fuel source for steam generation. These firemen oversaw the fire lighting at the plants before the 1960s.

History

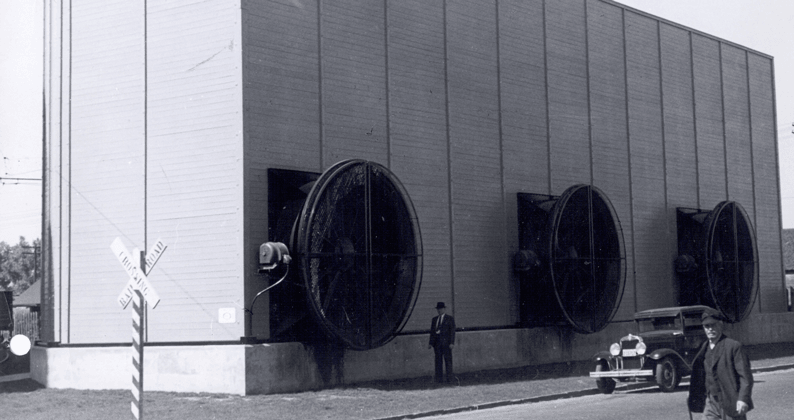

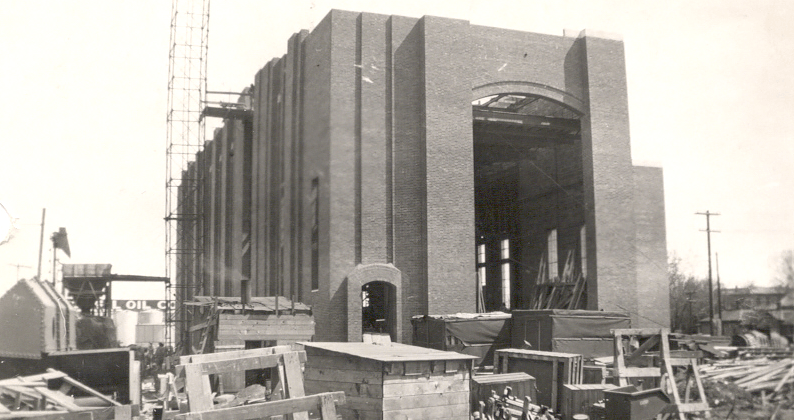

The CCUP was built in 1929-1930 as a coal-fired heating plant, replacing a smaller heating plant that had been located near Manter Hall. Trains would deliver carts of coal to the utility plant by means of railway tracks that were laid right next to the plant.

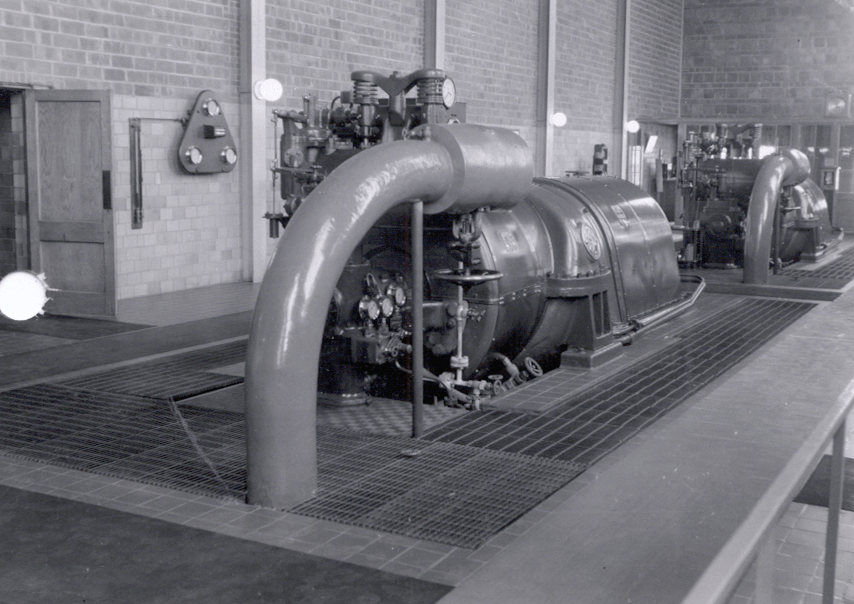

During the early 1930s, the heating plant became a power plant with the addition of electricity generating capabilities. Co-generation, the process of using a single fuel source (coal) to simultaneously generate two usable energy sources (steam and electricity), became possible with the addition of three General Electric steam turbines capable of generating 5,500 KW. Two 2,000-ton water chillers were added to the power plant during the early 1960s to provide additional comfort for campus building occupants during the sweltering summers.

The use of steam turbine-driven generators and water chillers required the addition of cooling towers. The cooling towers were erected outside the plant to make use of natural drafts, giant fans, and running water to evaporate the heat extracted from the chillers or to condense exhaust steam from the steam turbine-driven generators. Because the cooling process involves large amounts of running water, these towers had to be constructed out of redwood to be resistant to rotting. Today's cooling towers are made of more durable and lightweight composite material.