The innovative Centralized Renewable Energy System (CRES) leverages its close proximity to the Theresa Street Wastewater Treatment Plant to provide year-long heating and cooling to Nebraska Innovation Campus (NIC) without the use of steam boilers and water chillers. Instead, CRES sustainably warms and cools buildings by exchanging thermal energy (BTUs) from treated wastewater.

This central renewable energy system serving Nebraska Innovation Campus is one of only a few such systems in the world. We are demonstrating our commitment to innovation as well as to the environment. Dan Duncan Innovation Campus Executive Director

Cited Article

General Statistics

Staffing: Fully Automated (no Operators), shared maintenance

Campus Heat & Cool Distribution System: 1.1 Miles

TSWTP Effluent Water Loop: 0.77 Miles

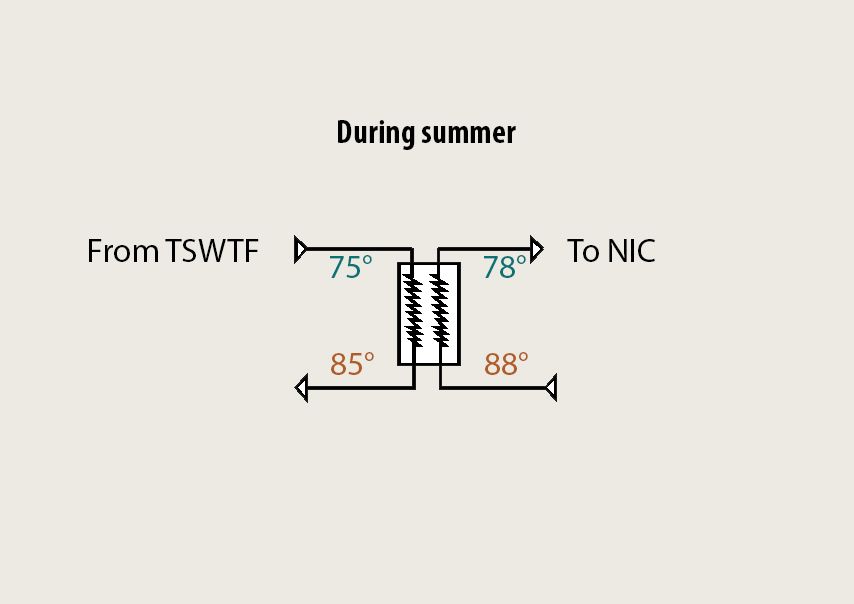

Comfort cooling temperature: 75°-78°F

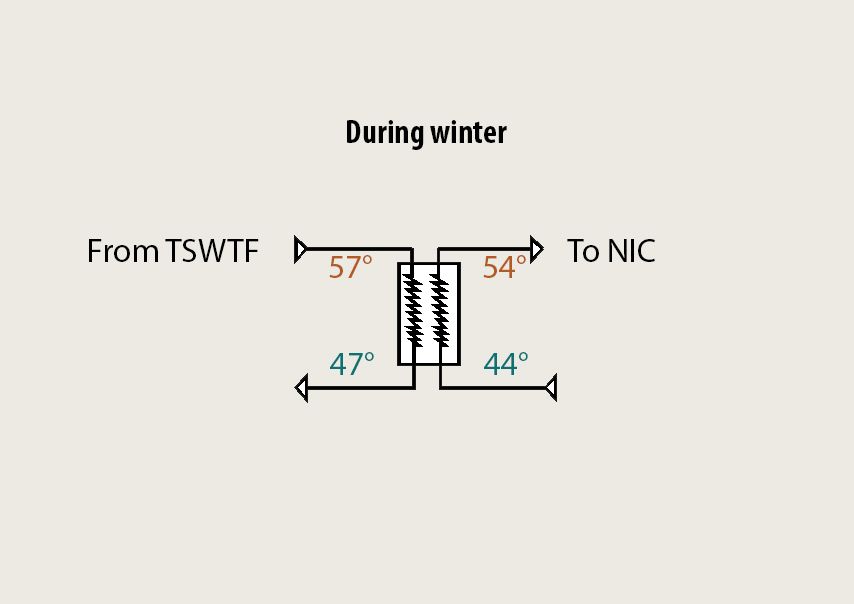

Heating temperature: 54°-57°F

Equipment and Fuel Profile

Equipment "trains" comprised of: 1 plate-and-frame heat exchanger, 1 pump @ 3900 gallons/minute, 2 filters

Equipment "trains" capacity: 6

Current equipment "trains" buildout: 2 with 1 spare

Amount of heating and cooling per heat exchanger: 1630 tons

TSWWTP Pump Station submersible pumps: 2 with 1 spare @ 5,000 gallons/minute

How CRES works

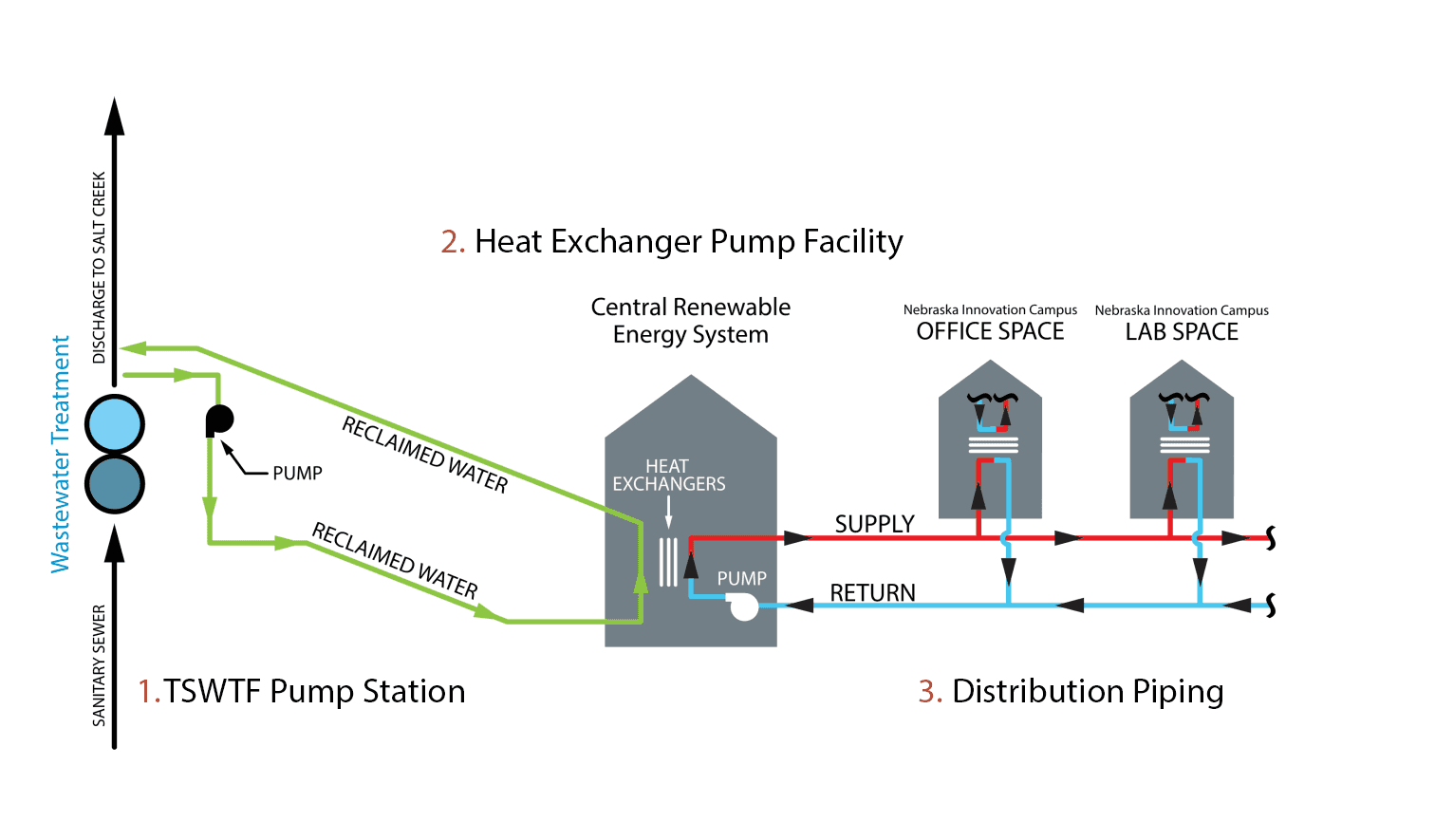

Completed in late summer of 2014, the CRES is made up of three main components: the Theresa Street Wastewater Treatment Facility (TSWTF) Pump Station, the Heat Exchanger Pump Facility and campus distribution system.

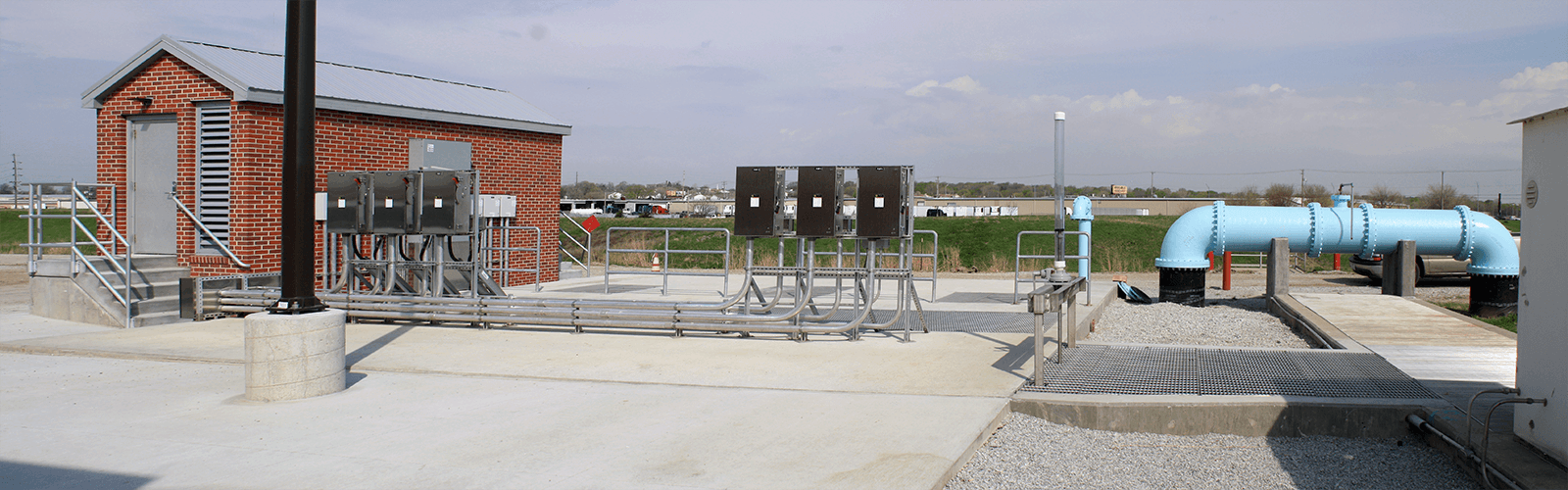

The TSWTF Pump Station is located by the effluent (wastewater) discharge outlet near the Salt Creek. Its multiple pumps partially divert the effluent to the Heat Exchanger Pump Facility in a self-contained water loop.

The Heat Exchanger Pump Facility is located on the edge of NIC’s northeast exit and houses three large plate and frame heat exchanger systems and a number of pumps. These heat exchangers provide a heat transfer medium for the TSWTF Pump Station water loop and the campus water loop.

Once the water loops have undergone their heat transfer process, the effluent water loop is then discharged back to the Salt Creek. The campus water loop is pumped into the campus distribution system to flow to campus office and lab space for heating and cooling.

CRES Heating and Cooling Process

The Centralized Renewable Energy System allows for campus heating and cooling with minimal carbon footprint, making it a very efficient, environment-friendly system. The diagrams below illustrate season-specific temperature changes in each water loop as the flow passes through the heat exchanger system.

Operations

One of the dynamic features of the CRES facility is that it can be operated 24/7 without staff on-site. The equipment is completely automated and linked back to the City Campus Utility Plant (CCUP), where operators remotely monitor and operate equipment.

The Heat Exchanger Pump Facility currently utilizes three of six available spaces for heat exchangers. As the campus expands, additional heat exchangers can be added to accommodate future heating and cooling needs. The facility also houses a water chemistry lab space, a single operations office and an electrical equipment room.

What is a Plate-and-Frame Heat Exchanger?

Plate and frame heat exchanger systems are constructed with thin, textured sheets of metal and gaskets that are sandwiched alternately and held together by thick metal frames on both ends. The texture of the metal sheets maximizes the heat transfer surface (a much larger surface area than with conventional heat exchangers) and guides water flow. The heat transfer process occurs when water from each water loop flows from top to bottom on opposite sides of each metal sheet.

History

CRES is a product of many exploratory discussions about sustainable alternatives to traditional boilers and chillers during the planning phase of Innovation Campus. The main requirement of alternatives was that they must be capable of providing year-long heating and cooling to the 2.2 million square foot campus. Studies were carried out to identify possible options.

In these studies, engineers noted the close proximity of the Theresa Street Wastewater Treatment Facility (TSWTF) to Innovation Campus and the relatively stable and moderate temperatures of the effluent from the facility into the Salt Creek during all seasons. The reclaimed water fluctuates between 57° Fahrenheit in winter and 75° Fahrenheit in summer.

Engineers then formulated a unique system - much like a geothermal system but using the wastewater as a heat sink rather than the Earth - to leverage those advantages. Construction began in fall 2013 and was completed in 10 months.