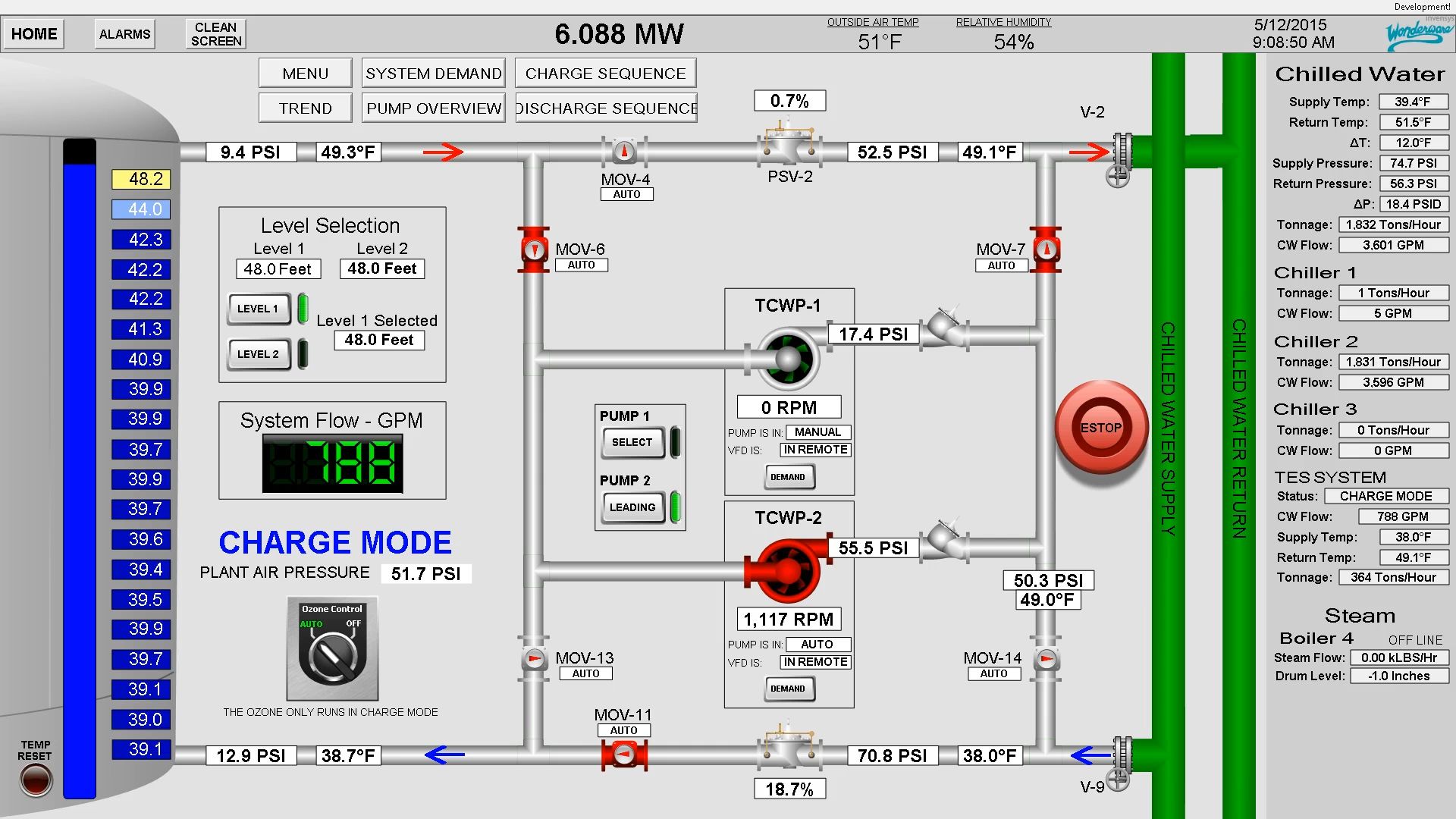

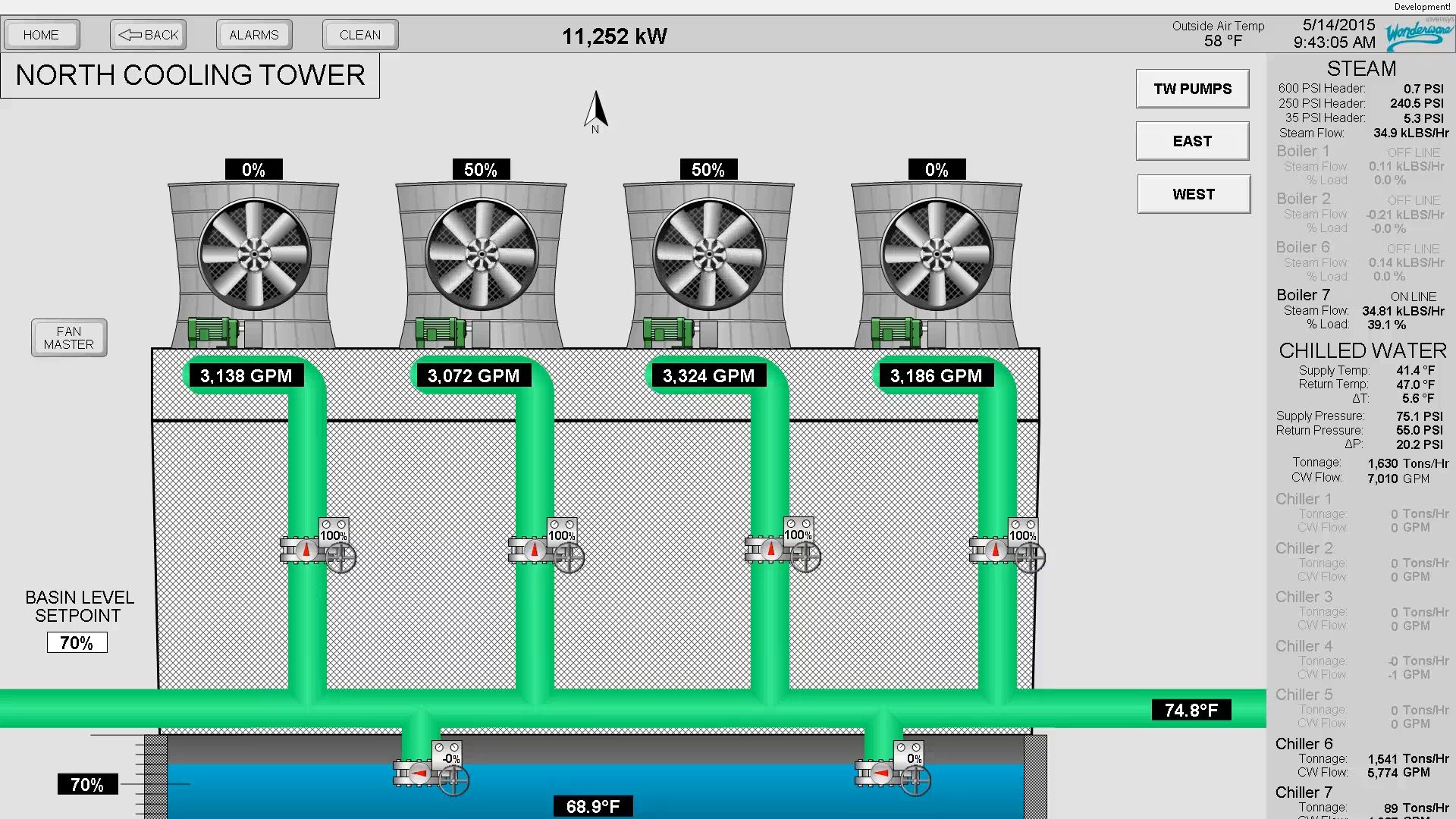

At all of our Utility Plant locations, automation is utilized in some manner with most pieces of equipment. Centralized utility plant alarm systems keep the operations staff informed of equipment operation, failures or process conditions that are outside of normal operating parameters. Leveraging the data from the instrumentation and control systems, we are able to reduce energy consumption and maintenance costs, increase operator effectiveness and improve reaction time to changes in process conditions.

Increasing Efficiency and Effectiveness

UNL utility plants use a combination of process automation standards for process control, monitoring, and historical data. Programmable Logic Controllers (PLC’s) and Process Automation Controllers are integrated into the utility plant’s control system network for local and remote control of equipment such as boilers, water treatment systems and cooling towers. All these data are then fed into a visual interface called Wonderware where all equipment's operational status can be monitored by on-duty operators.

The CRES plant is a fully automated system that responds to temperature changes in the thermal loop water at Innovation Campus and the temperature of the effluent water from the Lincoln Water System treatment plant. Automation allows this plant to be completely unstaffed; it is remotely monitored and controlled as needed to provide safe and reliable operation.

Secure industrial control networks are used in the utility plants to ensure reliability and reduce the risk of computer viruses, network attacks, etc. from affecting plant operations. System redundancy is integrated into the different campus locations to provide backup controls, data monitoring and a history of plant process conditions, events and alarms. Security cameras integrated into the UNL Police Department system allow the operations staff to visually monitor plant conditions from a remote location.

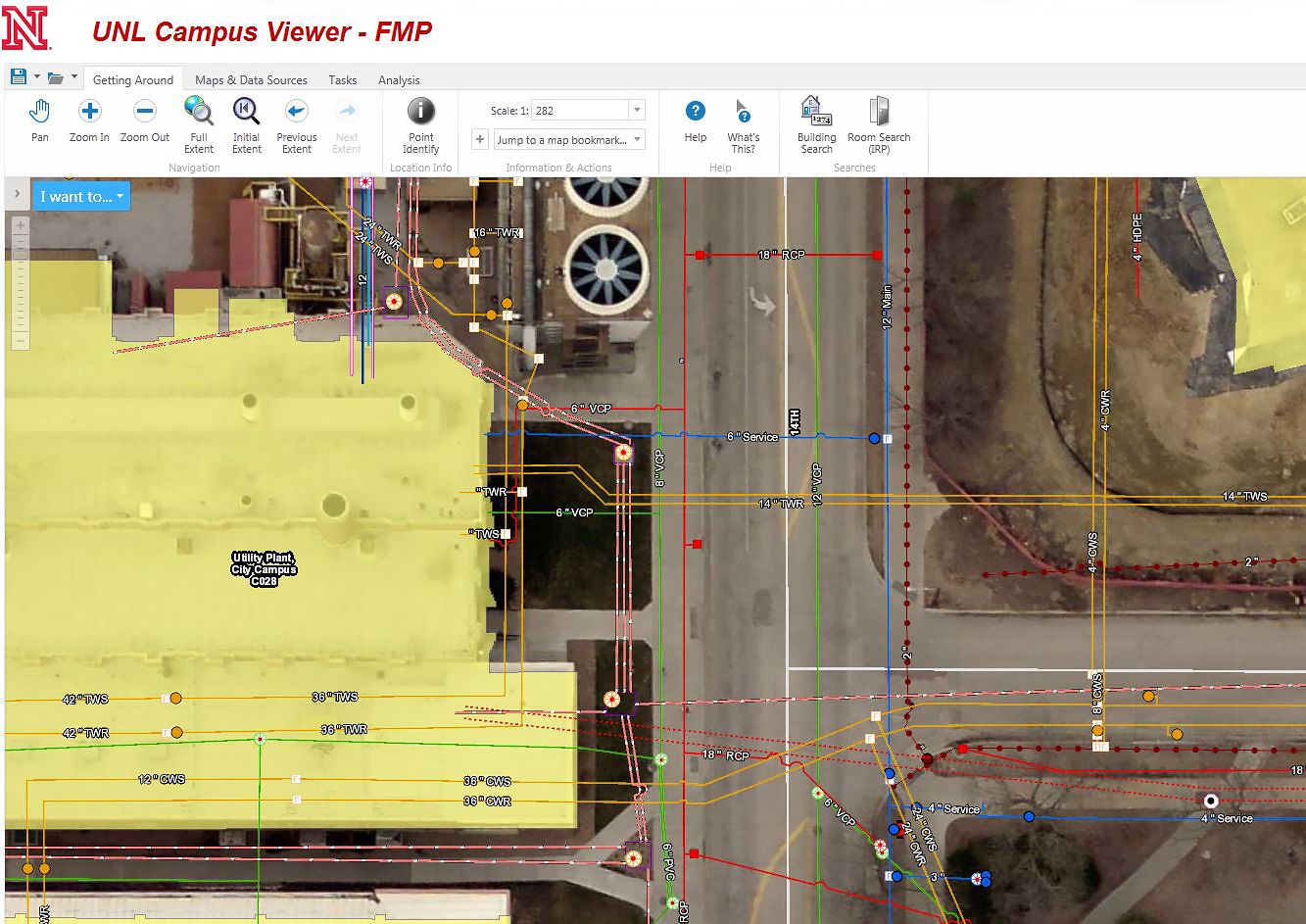

Looking Underground with GIS

Locating and mapping underground and surface utilities is always critical and importance to operations and maintenance. Utility Services benefits from an integrated view of our underground utilities and asset management by using geographic information system (GIS) technology. It provides a platform for real-time visual access of various utility systems and results in more efficient maintenance and timely response to service requests.

GPS mapping and survey-grade equipment are used to accurately locate when new systems are installed or existing systems are exposed. Accuracies consistently range from 1-10 cm.